Bad gasoline causes misfires, loss of performance, and stalling. Driving can damage the pump, injectors, and catalytic converter.

What to do immediately: stop and document the refueling → dilute with quality gas → check the water/octane level → change the filter → if water is detected, drain the tank.

Why Fuel Quality Still Matters Today

Modern engines squeeze more power from less fuel. However, efficiency depends on clean, stable fuel and a healthy fuel system. Direct injectors spray microscopic patterns that water can disrupt. Detergent packages and proper octane help gasoline ignite consistently at speed. Even hybrid cars still burn fuel under load. That’s why quality fuel still pays off today.

- Use reputable gas stations with high turnover and posted quality controls.

- Avoid fueling during tanker deliveries.

- Keep your gas tank at least a quarter full to protect the fuel pump.

- Replace the components on time and inspect the fuel lines periodically.

- Watch for symptoms after every fill and keep receipts from the gas station.

- Keep receipts when you buy gasoline and note the pump number; documentation simplifies any claim.

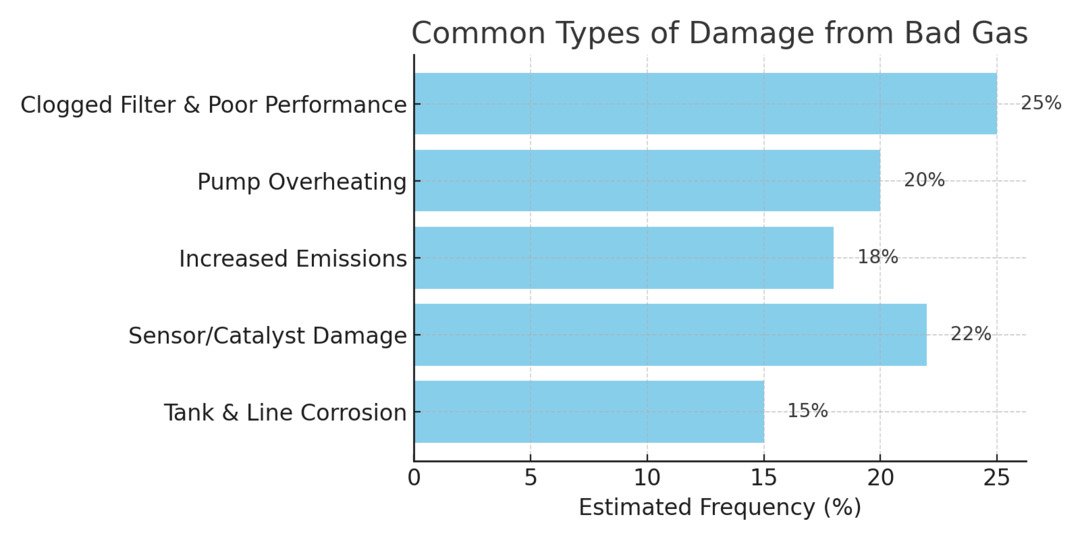

What Damage Does Bad Gas Usually Cause?

Bad gas contains water, oxidation by-products, or contaminants. That can lead to rough idle, throttle lag, and trouble restarting when hot. Bad gas also strips lubricity, accelerating wear in the fuel pump. In severe cases, rust and corrosion form in the tank and lines. If you continue to drive, the problem begins causing secondary failures.

When shopping used, scan records or check a vehicle history report to spot past fuel-related repairs.

- Clogged fuel filter, restricting flow and causing poor performance.

- Pump overheating from low lubrication or running with a near-empty tank.

- Dirty parts lead to sputtering and higher emissions.

- Sensor fouling and catalyst damage from unburned gas.

- Internal damage in the tank, lines, and rail from water and acidic by-products.

How Bad Fuel Affects Different Types of Vehicles

Not every vehicle reacts the same. Direct-injection gasoline engines have ultra-tight injector tolerances. Tiny debris instantly affects spray patterns. Turbo engines are more knock-sensitive. They require consistent octane to protect the powertrain. Diesel fuel systems operate at far higher pressures, so water or bacteria quickly score components. Older cars may tolerate slightly old fuel, but seals and hoses are more vulnerable.

| Vehicle type | Typical reaction to bad fuel | Common weak points | What to do first |

| Gasoline, port-injection | Hesitation, rough idle | Fuel filter | Drain the sample, change the component |

| Gasoline, direct-injection | Misfire under load, hard restart | High-pressure pump | Test octane/contaminants, add top-tier cleaner |

| Turbocharged gasoline | Knock, reduced performance, limp mode | Sensors, plugs | Dilute the tank with quality fuel, scan for codes |

| Diesel | Loss of power, “signs of bad diesel fuel” | Water separator, pump | Water test, drain separator |

| Older vehicles | Sputtering after sitting | Hoses, tank rust | Inspect tank, flush lines |

Before making a purchase, run a VIN decoder to confirm fuel type requirements and emission package.

Environmental Impact of Bad Gas

Contaminated or low-quality fuel not only affects your engine’s performance but also increases your vehicle’s emissions. When your engine struggles to burn fuel properly due to water, ethanol imbalance, or chemical impurities, it may release more carbon monoxide, unburned hydrocarbons, and CO₂.

Top Signs of Bad Gas in a Car

Bad fuel usually shows up within a few miles of a fill-up: rough idle or surging, hesitation on takeoff, and hard hot restarts. Under load, you may hear ping or knock while idle stays mostly smooth, and at stoplights the engine can stumble or stall. A sour/varnish smell or a cloudy, layered look in a quick clear-jar check are strong clues; you might also notice a sudden MPG dip, a louder pump whine, or a check-engine light (often misfire or lean/rich codes like P0300/P0171/P0172). If several of these appear right after refueling, treat it as a fuel-quality issue first.

Bad Gas vs Low Octane vs Misfueling

| Scenario | What it feels like | Quick fix (now) |

| Bad gas (contamination/aging) | Rough idle, surging, hard hot restarts | If safe, top off with fresh fuel to dilute → replace fuel filter → do a quick clear-jar check; plan a drain if you see water/layers |

| Low octane (wrong AKI) | Ping/knock under load, power cuts; idle usually OK | Add the correct octane (preferably Top Tier) → avoid heavy throttle; octane booster only as a short-term crutch |

| Misfueling (wrong fuel type) | Severe stumble or no-start soon after fill | Don’t drive. Tow → drain tank/lines → replace filter; inspect pump/injectors |

- Tow immediately if: flashing CEL, persistent heavy knock, repeated stalls, or visible water/phase separation.

- Keep proof: save the receipt + pump number, note time/mileage, and keep a sealed sample if you’ll file a station complaint.

Fuel Smells, Colors, and Textures: What’s Normal vs Not

Fresh gasoline should smell sharp but not sour, and look clear to slightly straw-colored. Dark, orange, or tea hues suggest contaminated additives. Cloudiness often indicates water. Feel isn’t recommended, but technicians note slickness; gritty residue signals dirt or rust.

Learn the bad gasoline color cues so you can catch problems early and avoid causing additional system damage. These observations are practical tips you can do quickly in your driveway.

| Observation | Normal | Not Normal | What it suggests |

| Color | Clear to pale straw | Dark orange/brown | Rust, old gas, degraded additives |

| Clarity | Transparent | Cloudy, hazy layers | Water or phase separation |

| Smell | Sharp gasoline odor | Sour/varnish odor | Expired gasoline, oxidation |

| Sediment | None | Visible rust | Tank damage, components |

Fuel left sitting in vented containers can oxidize measurably in weeks, raising gum levels.

How Mechanics Test Fuel for Contamination

A mechanic starts by drawing a clear-jar sample from the gas tank or fuel rail. After a quick swirl test, water or layers become visible. Next, shops may use phase-separation paste for water, and hydrometers or portable analyzers for alcohol and density. Scan tools check issue counts and fuel-trim response to confirm a fuel-quality issue rather than ignition faults.

- Lab checks and scan data help explore root causes instead of guessing.

- Jar test: look for layers, debris, and abnormal color.

- Water check: separation paste or simple settle time.

- Fuel-trim analysis during a drive.

- Filter cut open to inspect for rust, dirt, and varnish.

- Pressure/volume test for the pump.

How Sensitive Are Modern Engines to Bad Fuel?

Today’s engines run leaner, with higher compression and precise injectors. That efficiency makes them less forgiving of bad gas in a car.

Turbo models can pull timing, cutting capacity to protect parts. Because tolerances are tight, even short exposure to bad gasoline can accelerate wear, raising expenses later. Correct diagnosis prevents misreading misfires as powertrain faults.

What Makes Fuel Go Bad Over Time

Fuel degrades when oxygen, moisture, heat, and metals interact. Oxidation creates gums. Ethanol attracts water, which corrodes tanks and lines. Long periods of sitting let layers form, especially in partially filled tanks. Additives eventually deplete, making ignition less consistent.

If fuel is stored poorly for more than six months, expect starting difficulty and rough running. Knowing your gas tank size helps calculate safe dilution ratios precisely.

- Heat and oxygen accelerate gum formation.

- Ethanol blends absorb water, causing phase separation and corrosion.

- Partially filled tanks invite condensation and rust.

- Long sitting lets debris settle and layers form.

- Old gas loses volatility, making engines harder to ignite.

Is Premium Fuel Less Likely to Go Bad?

Premium gas doesn’t age more slowly by magic; it just starts with higher octane and robust detergents. If contamination enters, both regular and premium fuel degrade similarly.

However, top-tier premium gasoline often carries stronger additive packages that can keep internal parts cleaner, making symptoms less severe. Still, liquid will overwhelm any additive. Use quality fuel and good storage habits rather than assuming premium gas won’t turn into bad fuel.

Hidden Ways Fuel Gets Contaminated

Contamination doesn’t only happen at a gas station. Vented cans let moisture in. A rusty filler neck sheds debris into the tank. Parking on a steep road with a low tank can move sediment toward the pickup. Even new cars can face residue from fresh hoses.

These factors lead to subtle symptoms that are easy to overlook.

- Tanker delivery stirring sediment at pumps.

- Condensation from frequent short trips and a near-empty tank.

- Old lawn equipment cans poured into a car.

- Damaged fuel cap seals letting water in.

- Corroded filler necks dropping rust flakes.

How to Fix the Problem Without Wrecking Your Engine

If you notice symptoms right after a fill, stop driving. Add quality fuel to dilute, then test. Change the fuel filter if the flow drops. A mechanic can drain the tank through the service port, flush lines, and run a professional cleaner. Severe water requires full evacuation.

Don’t ignore stall events; repeated lean issues can cause capacity loss and catalytic damage. If unsure, schedule an appointment with a qualified mechanic to ask about how to treat bad gas in your car before trying additives.

- Document the station, date, and receipt.

- Top off to dilute with quality fuel if safe to continue.

- Change the fuel filter.

- Perform a pump volume/pressure test.

- Scan, fix misfire codes, and road-test for stable response.

Can You Get a Refund or Sue the Gas Station?

Yes, if you can prove bad gas. Keep receipts, tow records, and test results. File a complaint with your state weights-and-measures office.

Many stations carry insurance for contamination claims. You’re more likely to recover costs when multiple cars report issues the same day. Start with the station manager, then escalate with written documentation.

Fuel-Quality Complaint — Quick Checklist

- Save proof: receipt with station address, pump #, time, grade.

- Photos: pump labels/price sign, octane/E15 decals, odometer/CEL.

- Sample: 100–200 ml into a clean clear glass jar, before any additives; label date/time, VIN, station/pump; seal.

- Chain of custody: note who collected, when, where stored, hand-offs; keep sealed, cool; take photos.

- Shop note: brief report with DTCs, trims, fuel pressure/volume, photo of cloudy/layered fuel; bag the used filter.

- File & escalate: write the station manager (ask for insurance contact) and submit to State Weights & Measures; keep a contact log.

Summary

Bad gas can sneak up fast: tank damage, sputtering, and difficulty starting are early signs. Act quickly. Document, test, and dilute with quality gasoline. If liquid is found, drain the tank and fuel lines. Use reputable gas stations. Keep the tank above one-quarter. Replacing parts on time. This all will help prevent most issues and protect your engine and fuel pump from unnecessary costs.

Frequently Asked Questions

Yes. Summer heat accelerates damage, while winter condensation is fraught with a cold-start challenge. You may notice longer cranking or stumble in cold weather and more vapor-lock-like symptoms in hot stop-and-go drive conditions.

If bad fuel is confirmed as the cause, manufacturers can deny coverage for related damage. Keep receipts and use quality gas. A dealership may request samples. Damage from bad elements isn’t a defect; it’s outside normal warranty coverage.

Hard braking can slosh fuel away from the pickup in a low tank, exposing the pump to air.

- Low fuel level moves sediment toward the pickup.

- Water layers shift and reach the pickup first.

- A weak fuel pump can’t maintain pressure during slosh.

- A clogged filter exaggerates momentary starvation.

In typical conditions, noticeable degradation starts within a few months. After six months, liquid absorption can cause rough idle and hesitation. Hot climates and vented storage can accelerate aging significantly.

Look for a flashing check-engine light, fuel-trim or lean-condition codes, and reduced-power messages. Persistent EVAP or injector codes after a recent fill can indicate contamination. Scan promptly to prevent additional damage to the catalytic system.